Manufacturing Industry

Increase Manufacturing

Speed and Efficiency

Custom corrugated plastic solutions

streamline operations and enhance products

Manufacturers use Wave-Core™ corrugated plastic solutions for various applications, including shipping and packaging, moving parts and materials within the manufacturing environment, and enhancing end products. The versatility and durability of Wave-Core™ make it the perfect choice to streamline manufacturing operations and improve products.

Manufacturing solutions for

Wave-Core™ corrugated plastic rolls

Wave-Core™ corrugated plastic can provide significant value to manufacturing operations, particularly regarding product movement, handling, and packaging. Custom corrugated plastic totes and bins allow manufacturers to move products efficiently within manufacturing environments. Our customers employ a closed-loop system, using boxes, bins, or totes to move parts and products around their facilities. Boxes can be broken down and re-assembled to use again as a way to reduce waste and control costs. Wave-Core™ can also be used to create custom stackable totes or nestable totes to conserve space in manufacturing environments.

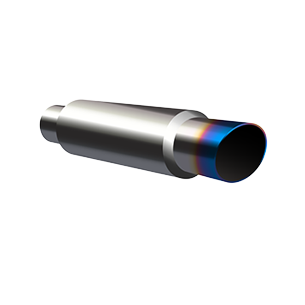

For product handling, Wave-Core™ can be used for slip sheeting to create spacers between products to avoid damage from forklifts and can reduce pallet use. For products with unique shapes, such as mufflers, furniture, tools, or equipment, Wave-Core™ rolls or sheets can be interwoven between individual pieces to provide added protection when a slip sheet is insufficient.

The durability of our HDPE material makesWave-Core™ ideal for outdoor storage solutions or protecting high-value products. Whether you need a die-cut tray or box, a fully custom packaging solution, or customized rolls, our designers can help you create a unique solution to meet your manufacturing needs.

Design Your Custom Solution

Use Wave-Core™ to enhance

finished products

In addition to protecting and moving products, Wave-Core™ can be used within product designs to enhance end-use applications. Various applications utilize our product, such as architectural paneling, internal reinforcement in durable packaging, component parts that offer lightweight and durable support, flanges, end caps, corner protection, and durable inner and outer protection.

We can easily die-cut Wave-CoreTM into ready-to-assemble inserts for a variety of applications, accelerating production. Wave-CoreTM can also be laminated with adhesives, fabrics, and other materials to create structural panels, dunnage, and other components. In applications where enhanced performance is required, Wave-Core can be made with flame retardants.

To experience all the benefits of Wave-Core™ corrugated plastic, contact us, and we'll explore your project requirements and how our products and manufacturing capabilities can enhance your end products.

Find Your SolutionEND USE APPLICATIONS

- Architectural paneling

- Internal reinforcement for packaging

- Component parts

- Flanges

- End caps

- Corner protection

- Internal and external protection

CUSTOMIZATION

- Laminated with adhesives & other materials

- Internal & external structural panels

- Dunnage and other component parts

- Flame retardants

Plastic recycling bins

and trash containers

Despite efforts to minimize raw material consumption, manufacturing operations still generate significant amounts of waste and recyclable material. Corrugated plastic is optimal for creating recycling bins and trash containers in custom sizes to meet your needs..

Wave-CoreTM is made from durable HDPE that won't be damaged by moisture or normal wear and tear. With custom plastic recycling bins and trash containers, you can keep your manufacturing environment clean while optimizing your recycling processes.