Wave-Core™ Prevents Damage During International Transportation

Project Overview

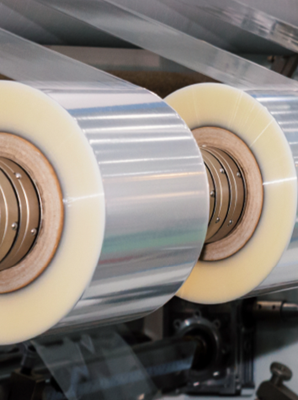

Transporting highly valuable materials, like sensitive films or delicate fiber optic cables,

requires careful attention to detail—and the highest protection possible.

This need for quality protection only heightens when the shipment’s destination is overseas. Our aerospace client needed a high-quality shipment solution that would protect their film products during international travel. Additionally, this solution needed to facilitate handling—efficiently packaging the rolled products for easier transportation.

Industries:

- Films

- Fiber Optic Cable & Wire

- Rollers

- Pipe and Pipeline

- Transportation

- Warehousing

Challenge

The protective solution must withstand all stages of transportation. An oversight in protection quality could cause loss in valuable product, weeks in transit time, and numerous delays for the final output. The client needed a solution that could:

- Protect large circumference area

- Withstand warehouse handling and international transportation

- Reusable for multiple applications

- Print the company name and instructions on material surfaceCustomization of colors

- Customize colors of shipment solution

Solution

Solution

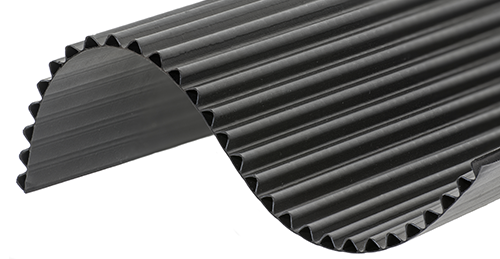

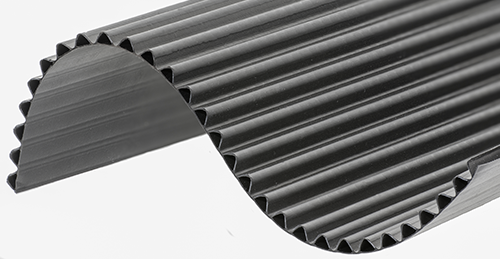

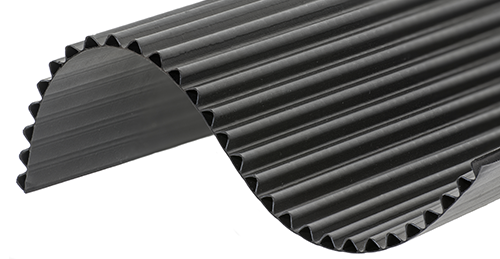

Using our Wave-Core™ corrugated plastic, we provided a durable, flexible wrap solution to our clients, which was customized to include their company’s branding and colors. To further customize the solution, one product used the Wave-Core™ single-face option, and the other used the double-face flexible solution. Both facings seemlessly flex, roll, and bend without needing additional steps, such as scoring for a tighter fit and smooth finish.

Using our Wave-Core™ corrugated plastic, we provided a durable, flexible wrap solution to our clients, which was customized to include their company’s branding and colors. To further customize the solution, one product used the Wave-Core™ single-face option, and the other used the double-face flexible solution. Both facings seemlessly flex, roll, and bend without needing additional steps, such as scoring for a tighter fit and smooth finish.

The Wave-Core™ team:

- Created a durable solution to prevent damage

- Created a returnable and reusable closed-loop solution

- Reduced loss inventory costs

- Improved operational efficiancies and costs

- Provided customized branding

Services Provided

- Wave-Core Material

- Custom size solutions

- Single and double-face ptions

- Custom Colors

- Custom Printing

- 100% recyclable

- 100% reusable packaging

Download Case Study