Liberty Plastics Increases Turns 8,000% for Large Food Manufacturer

Project Overview

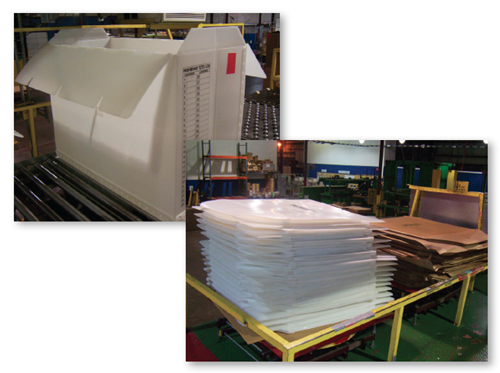

Your production materials shouldn’t cause disruptions to the manufacturing process—that’s just counterintuitive. When a multi-national food manufacturer’s paper boxes caused jams and shutdowns during production, Liberty Plastics, Inc. stepped in and offered a more durable, reusable, corrugated paper box solution—one that could withstand the moisture-rich factory envi-ronment. We created a custom solution that would streamline the production process and deliver measurable savings long-term.

Challenge

Liberty Plastics needed to find a solution that could withstand 50 turns and deliver measurable business growth over time. Boxes needed to:

- Store flat and quickly pop into shape

- Withstand wet environments

- Withstand automated machines

- Withstand 50 cycle turns

- Come in a recycleable material

Solution

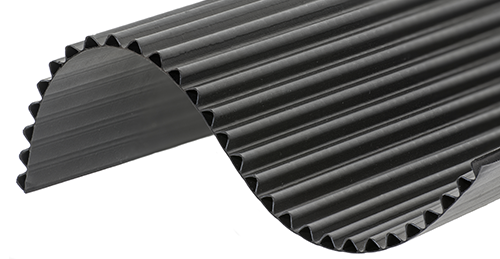

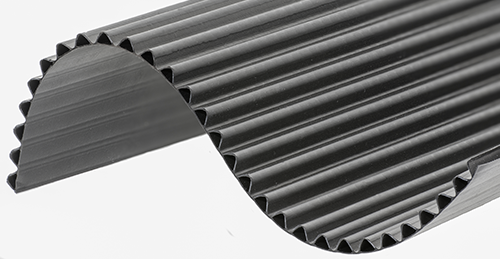

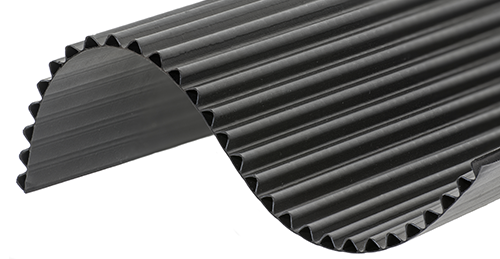

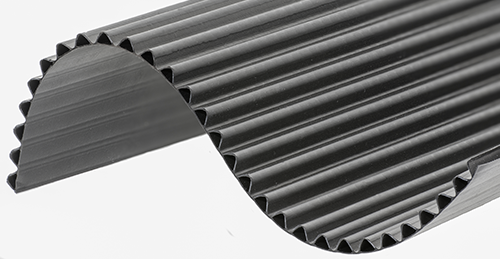

We achieved 80+ turns with our reusable packaging solution, which comes without glues or staples. The HDPE corrugated material offered the right durability, strength, rigidity, and moisture resistance to see on-time production and cost savings over time.

- Achieved over 80 turns.

- Interior arm and bottom tray design.

- Chart printed on side to measure turns.

- HDPE corrugated to withstand moisture.

- Collapsable design lies flat.

Services Provided

- In-house custom design capabilities

- HDPE corrugated material

- Die-cut & scoring

- Printing

Download Case Study