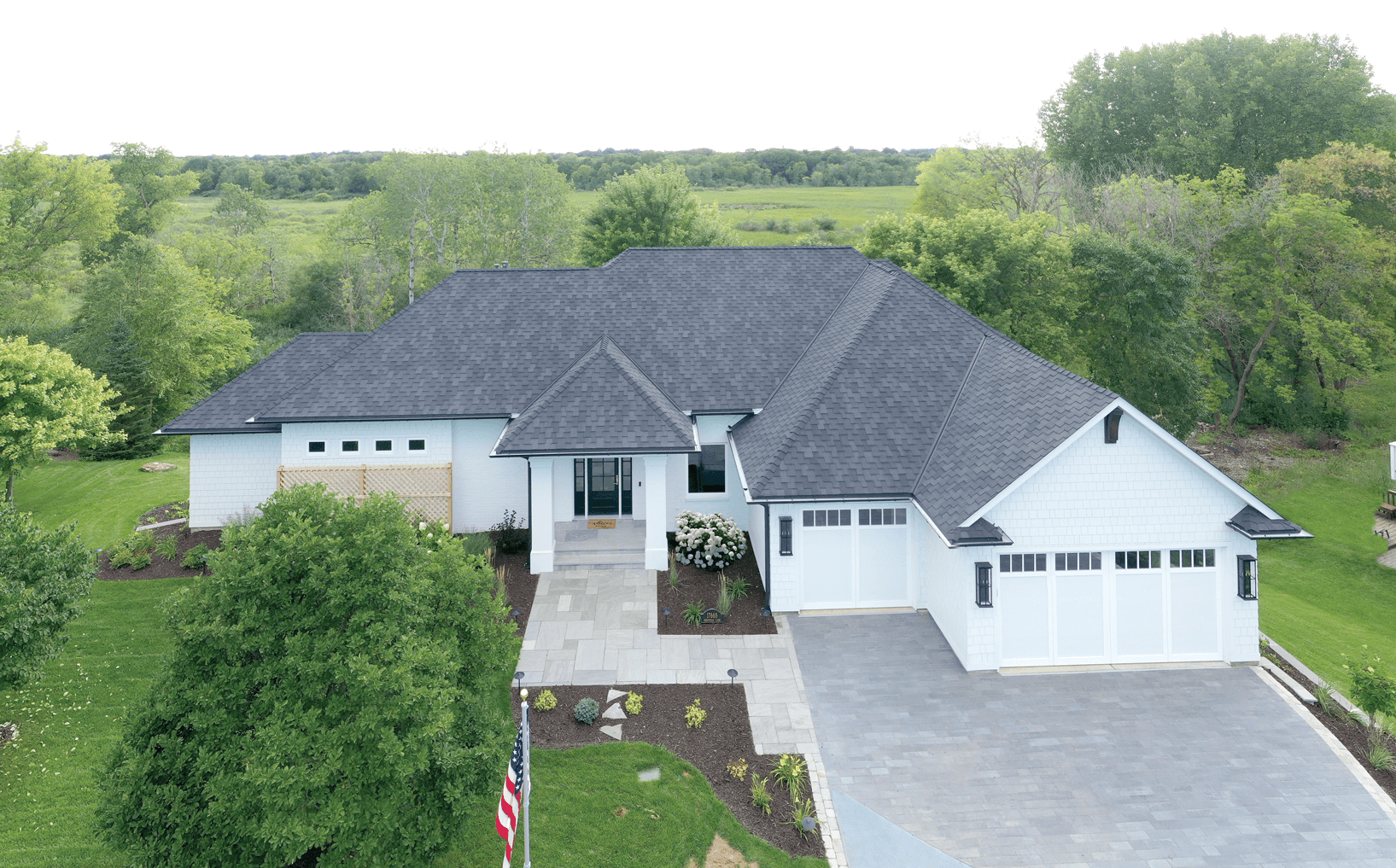

What's the best roofing solution? We'd argue it's whatever makes the roof disappear into the background. Because when it rains, the less the homeowner has to worry about what's happening above the ceiling and the attic, the better. A roof that protects against leaks years after your crew laid the final shingle in place results in happy customers and reflects well on your brand and quality.

But challenging weather cycles can shorten the lifespan of any roof. High-quality shingles, expertly laid to prevent the infiltration of moisture, are just part of the equation. The key to a dry roof that lasts for years is choosing rugged materials that resist moisture and effectively funnel it away.

However, using standard roofing materials can cause problems down the line. All it takes is a tiny gap or opening to let in moisture that kicks off a progression of mold, rot, unwanted leaks, shingle buckling and other problems for the homeowner.

A resilient roof calls for a rugged, water-resistant material that protects the underlying roof deck. Using the right kind of corrugated plastic can make your company known for its long-lasting, durable roofs that effectively seal out elements for decades. That’s why Wave-Core™ by Liberty Plastics has been a trusted material in roofing applications for decades.

Plastic vs. wood in roofing materials

At the basic level, corrugated plastic has several property advantages that prevent the issues that often occur in other building materials.

Lightweight

For starters, corrugated plastic is lightweight, giving it an advantage during shipping, sizing and installation, reducing the instance of worker injury and property damage.

Resistant to rot

Plastic resists water and moisture, eliminating concerns about the underlying rot that would cause the roof deck to split and break apart.

Provides channels

With proper positioning, corrugated plastic comes with built-in channels that effectively funnel moisture out from under the shingles. With less opportunity for moisture to collect, freeze, and allow mold and water

damage to propagate, corrugated plastic can be a better alternative.

Which plastic is rugged enough for a roofing application? HDPE

In a roofing application, not any plastic will do. Durability is non-negotiable. After all, it shouldn’t soften or melt when direct sun raises the rooftop temps to triple digits. At the same time, it must be strong enough to take a nail during installation. Very few materials come with the essential properties for rooftop applications.. However, HDPE corrugated plastic is one of the few that does.

What makes HDPE corrugated plastic a top choice for roofing applications?

Resilience

HDPE plastic is one of the strongest plastic materials in the market, known for its high tensile strength and impact resistance. Compared to other formulations, HDPE corrugate is better equipped to withstand the stress of stapling and nails without splitting and hold up after a hailstorm.

Weather resistance

On a rooftop, there’s no escaping the weather. The better your materials can withstand the climate conditions, the longer the roof will last. HDPE fits the bill because it's known for enduring through frost cycles and heat waves. It won’t become brittle or crack from exposure to arctic temperatures, nor does it soften under triple-digit heat. For additional resilience, HDPE resins can also be formulated to enhance UV resistance.

Attic protection by Quarrix

Ventilation products specifically designed to combat the elements of heat, moisture and Mother Nature in your attic while maintaining a clean and neat rooftop appearance.Quarrix has used Wave-Core for ridge ventilation, roof battens and soffit ventilation for decades because it has the lightweight, moisture-resistant, durable properties to help maintain a sound dry roof.

Wave-Core is an effective way to extend a roof’s longevity — giving your customers the freedom to enjoy a rainy day.

- Corrugated fluting creates additional channels that enhance airflow and channel away the rain, preventing moisture infiltration.

- Wave-Core is made entirely of corrugated HDPE, a material that’s highly resistant to UV, moisture, and temperature extremes. Though lightweight, it's also remarkably tough and durable.

- Because it resists rot, splitting, mold and cracking, Wave-Core is a longer-lasting alternative to other roofing products.

Let us design your solution

Whether you're ready for a quote or researching your options, we're here to help. Contact us to learn more about our durable plastic solutions for construction and building with Wave-Core.

< GO BACK | NEXT POST >